Choose your best ceramic pipe liner for next-level wear protection

Any pipe that is used to carry corrosive or abrasive fluids is exposed to abnormal wear and tear. The continuous flow of these media causes irreparable damage to its inside parts and fittings, which results in reduced performance and high maintenance costs. Pipe bends bear the brunt most often because it’s where slurries, tailings, or whatever is being transported rapidly changes its direction. They are the hardest areas to reach and call for coatings made with pinpoint accuracy to fit them. Fortunately, Chemshun Ceramics and our range of ceramic pipe liners have got you covered.

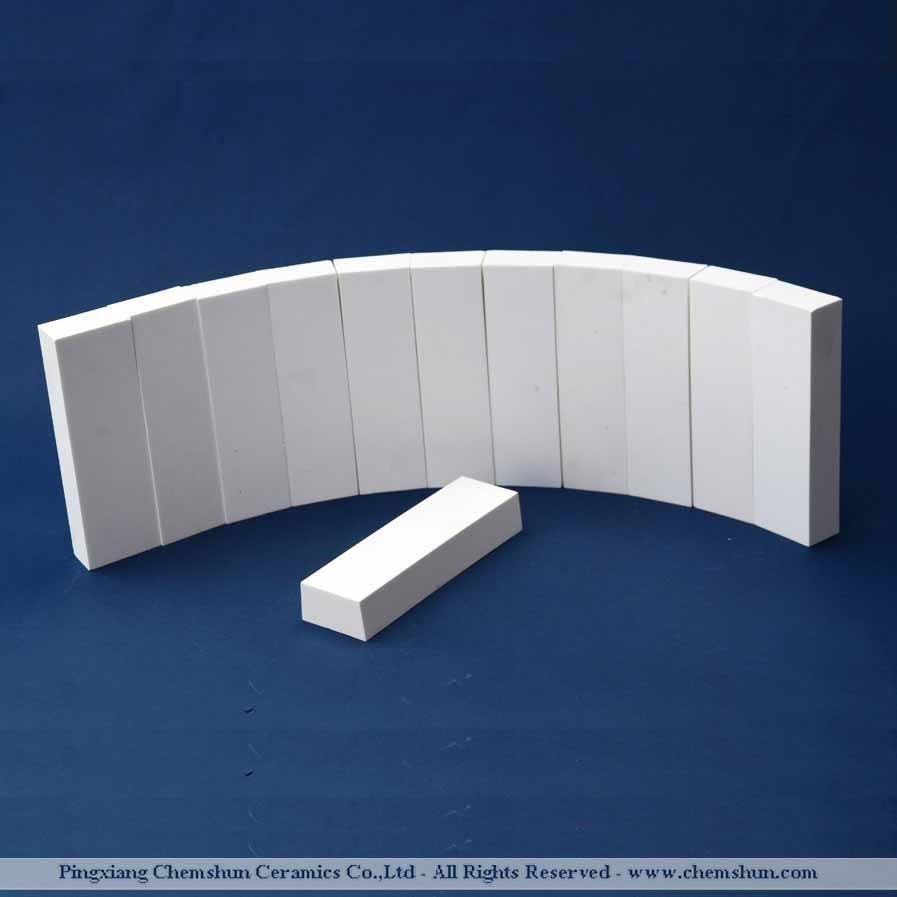

We do our utmost to design fillers in a variety of shapes to match the inside form of your piping and fittings. As of now, they are available as cones, cylinders, trapezoid tiles, rings, elbows, tubes, etc. This diversity allows you to pick the right ceramic pipe liner so that it can effectively minimize friction and damage associated with the flow of abrasive media.

Even if you can’t find a perfectly shaped coating for your applications, don’t fret. At Chemshun Ceramics, we are capable of fulfilling orders with custom drawings to suit your specific requirements.

Available types of ceramic pipe liners

The design is not the only thing to factor in when choosing your lining option. You should also keep the ins and outs of intended applications in mind. According to them, you may either benefit from high-grade alumina, zirconia, or silicon carbide ceramic pipe liners. They can all be found in our assortment, each with its unique features:

· Alumina. Best known for its physical and chemical resistance properties, alumina is a perfect ceramic material to prolong the service life of fluid transfer systems, slurry pipelines, and tubes used in metallurgical, electric power, and other industries.

· Zirconia. This is another ceramic material of the oxide type. Its most prominent feature is all about its superior mechanical strength backed up by improved corrosion and abrasion resistance. Plus, zirconia can greatly contribute to structure smoothness.

· Silicon carbide. A ceramic pipe liner made of this non-oxide enables you to take advantage of the low thermal expansion coefficient and density. With these and other features, silicon carbide is commonplace in pharmaceutical, chemical, and even papermaking applications.

Take a look at more detailed specifications and technical data on our pipe lining products before ordering. This will help you make a well-informed decision.

-

Curved Pipe Tile Liner

Curved Pipe Tile Liner -

Alumina Ceramic Pipe Liner

Alumina Ceramic Pipe Liner -

Trapezoidal Pipe Tile

Trapezoidal Pipe Tile -

90 degree pipe elbow

90 degree pipe elbow -

Cyclone Pipe Liner

Cyclone Pipe Liner -

92% Aluminium Oxide Pipe Ring

92% Aluminium Oxide Pipe Ring -

Alumina Ceramic Irregular Pipe Tube

Alumina Ceramic Irregular Pipe Tube -

Ceramic Lined Pipe Mainly For Lithium Battery Industry

Ceramic Lined Pipe Mainly For Lithium Battery Industry -

Silicon Carbide Tube

Silicon Carbide Tube -

Zirconia Ceramic Piston Pump

Zirconia Ceramic Piston Pump -

Ceramic Cone

Ceramic Cone -

Alumina Tube

CHEMSHUN Product

abrasion resistant ceramics

ZTA Ceramics ★★★★★

Zirconium Ceramics

Silicon Carbide Products

Ballistic Protective Ceramic

Ceramic pipe liner

engineering ceramics

ceramics lined equipment

rubber ceramic liner

Ceramic Grinding Media

- Alumina Grinding Ball & Cylinder

- Zirconia Ball/ Beads

- Zirconia Silica Grinding Beads

- Grinding Ball for Ceramics

- Mill Ceramic Bricks Liner

- Grinding Balls for Cement Mill

- Grinding Balls for Mining/ Mineral

99.7 Alumina Plate ★★★★★

Ceramic Rubber Hose

99 Alumina Tube

catalyst carrier

Foundry Ceramic Sand

Ceramic pump

Epoxy Resin Glue

Contact Chemshun

TEL:+86-799-6790781

FAX:+86-799-6790785

Mail:office@chemshun.com

ADD:Non-metal area of shangliuyuan, Economic development zone, pingxiang city, Jiangxi province, P.R.China